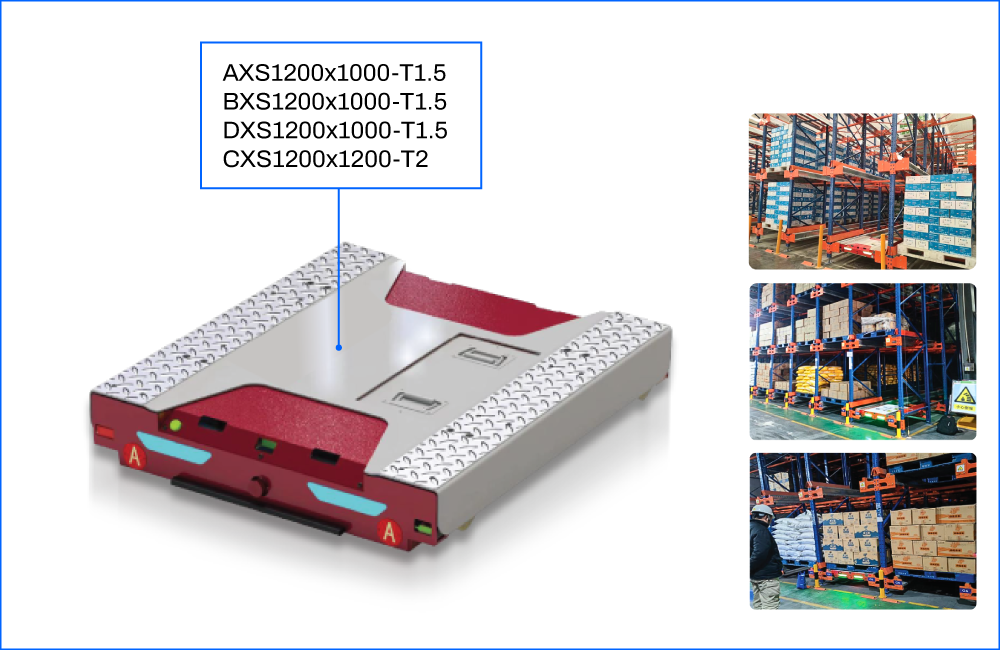

Pallet Shuttle System

Four Way Pallet Shuttle System (Heavy Duty)

TTF TECH : Four Way Pallet Shuttle System (Heavy Duty)

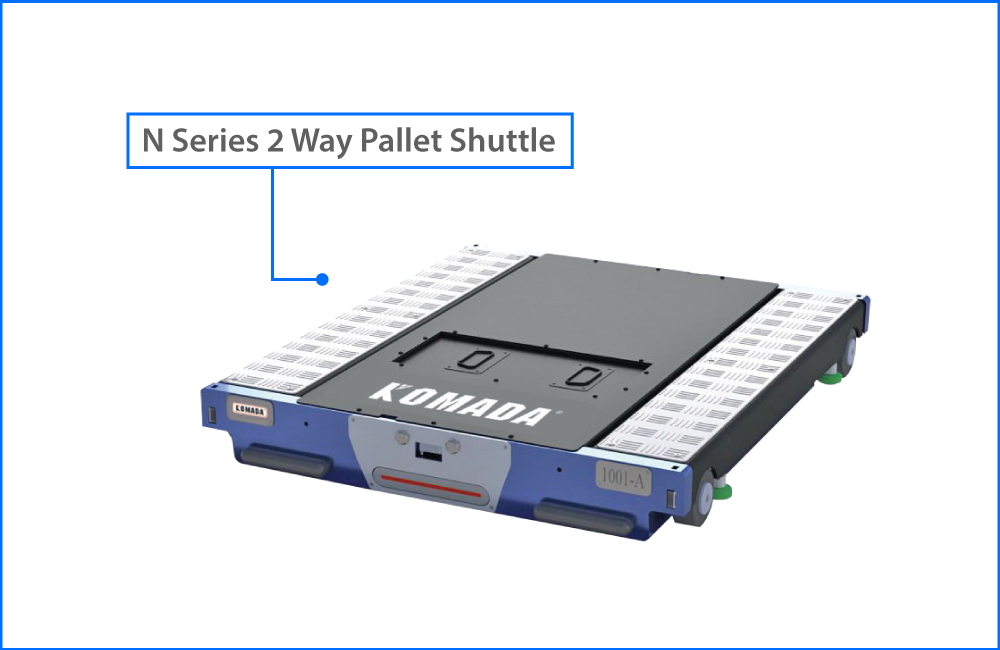

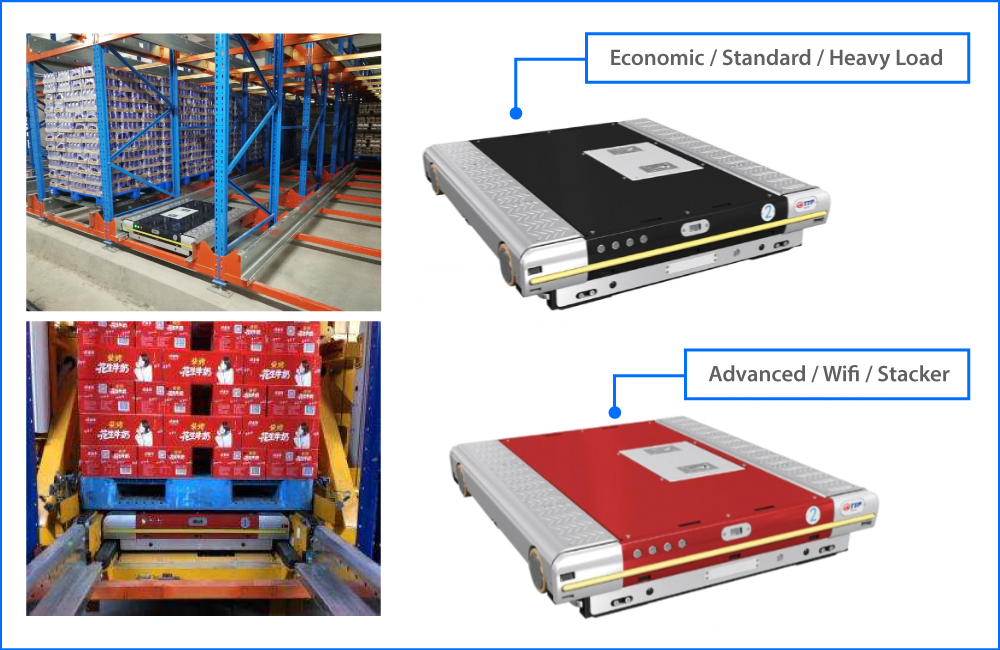

The Four-Way Pallet Radio Shuttle is an advanced automated storage and retrieval solution for handling palletized goods. This high-density system, an upgrade from the standard radio shuttle, is ideal for industries with large quantities and few SKUs, such as food & beverage, chemicals, and third-party logistics. The shuttle can move in four directions within both storage and main lanes, allowing it to switch lanes without forklift intervention. This capability significantly reduces labor costs and enhances warehousing efficiency.

Product Features:

Rated load: 2200kg

Thickness: 180mm

Accuracy Positioning:

- Positioning accuracy: 2mm ±

Flexible Planning:

- Intelligent path planning & multi-vehicle scheduling

Running Safety:

- Pallet calibration & obstacle perception

- Four-way driving

Advantage:

Enhanced Storage Capacity

Increases storage capacity by 3-4 times compared to traditional racking systems.

Cost-Effective and Time-Saving

Reduces land and labor costs, making it a more economical solution.

Fully Automatic Operation

Minimizes risk and potential damage to equipment and operators with automated functionality.

Integrated WMS/WCS System

Custom-designed Warehouse Management System (WMS) and Warehouse Control System (WCS) ensure seamless integration with the shuttle system.

Flexible Storage Solutions

Adjustable shuttle quantity allows for meeting diverse storage capacity demands.

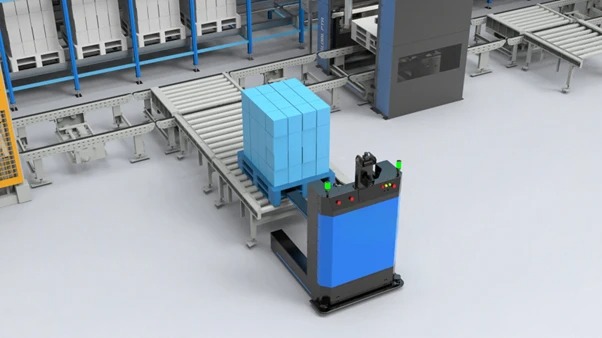

The 4-Way Pallet Shuttle is a high-efficiency, intelligent robotic system designed to automate pallet movement in high-density racking systems. Unlike traditional racking system, where you rely heavily on manpower especially stock management. With Pallet Shuttle Racking, its pallet radio shuttle can help to transport and handling all your goods in storage racks. It is specially suitable to high turnover warehouse, where the pallet shuttle system can help you to handle all the goods for a faster outbound process.

Refer the above video for a clearer understanding of how this pallet shuttle system help you in terms of inbound and outbound process.

It can move in four directions ( left, right, forward, and backward). Suitable for high-turnover warehouses, where the pallet shuttle system speeds up the handling process and supports faster outbound shipments.

Perfect for: Cold storage , E-commerce fulfillment centers , FMCG & manufacturing warehouses, 3PL, Health Care and high-turnover distribution hubs

Why Choose Our 4-Way Pallet Shuttle?

INBOUND PROCESS

OUTBOUND PROCESS

✅ Maximize Storage Space

The 4-way movement allows high-density racking designs. Free out all the space from the limitations of forklift aisles. Increased storage capacity by around 30% - 200%!

✅ Increase Operational Efficiency

With WCS/WMS integration, warehouse management system will direct pallets for faster turnaround times. .

✅ Reduce Labor & Operation Costs

Fully automated operations mean less reliance on manpower, fewer errors, and 24/7 operation.

It helps solve common issues such as:

-

Wrong goods delivery due to human picking errors

-

System shows stock, but physically unavailable due to workers simply locate the pallet goods in the wrong location or empty rack spots. End up forget where they have located!

-

Slow picking and retrieval time.

-

Reduced Operational Cost from long term labor and error-related expenses